Multiple sleeves can be installed at different depths to operate production zones independently or in some cases to commingle production were applicable.

Sliding sleeve door oil and gas.

The packoff assembly isolates the sliding sleeve ports and prevents fluid migration between the tubing and casing annulus while allowing restricted flow up the production tubing from below.

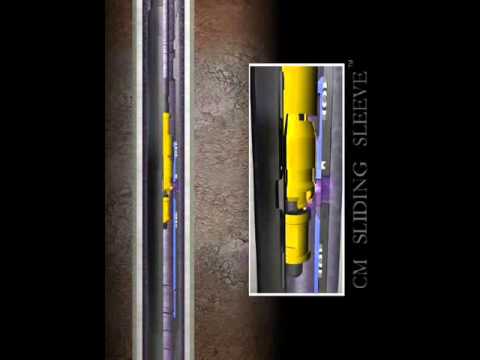

It incorporates an internal sleeve that when open enables communication between the tubing and tubing casing annulus.

Sliding sleeve english español.

The sliding sleeve packoff is attached to a lock which anchors and seals in the sliding sleeve.

Sliding sleeves are high performance equalizing components allow communication between the tubular and annulus for circulation or selective zone production in a completed oil or gas well.

Their main uses are to shut off flow from one or more reservoir zones or to regulate pressure between zones.

A sliding sleeve is a standard component for the completion of an oil or gas well.

Sliding sleeves are and integral component of most completion strings used to open and close communication between the annular area and tubular area of completed production oil and gas well.

It uses switch tool to move the internal sliding sleeve up and down to open or close the sliding sleeve.

Well completions a completion device that can be operated to provide a flow path between the production conduit and the annulus.

The durasleeve sliding side door circulating and production sleeve is a full opening device that can be operated using standard slickline methods.

Sliding side door sleeves are a robust and reliable method of isolating the tubing id from the reservoir for a variety of reasons including but not limited to fluid loss control activation of hydraulically set down hole tools zonal stimulation and production and icd shutoff for ultimate production control.

Sliding sleeves incorporate a system of ports that.

During operation we just need to drop down the plug and use wire lines to switch the cyclic sliding sleeve in order to replace the casing protection fluid kill the well and some other purposes without damaging the formation.