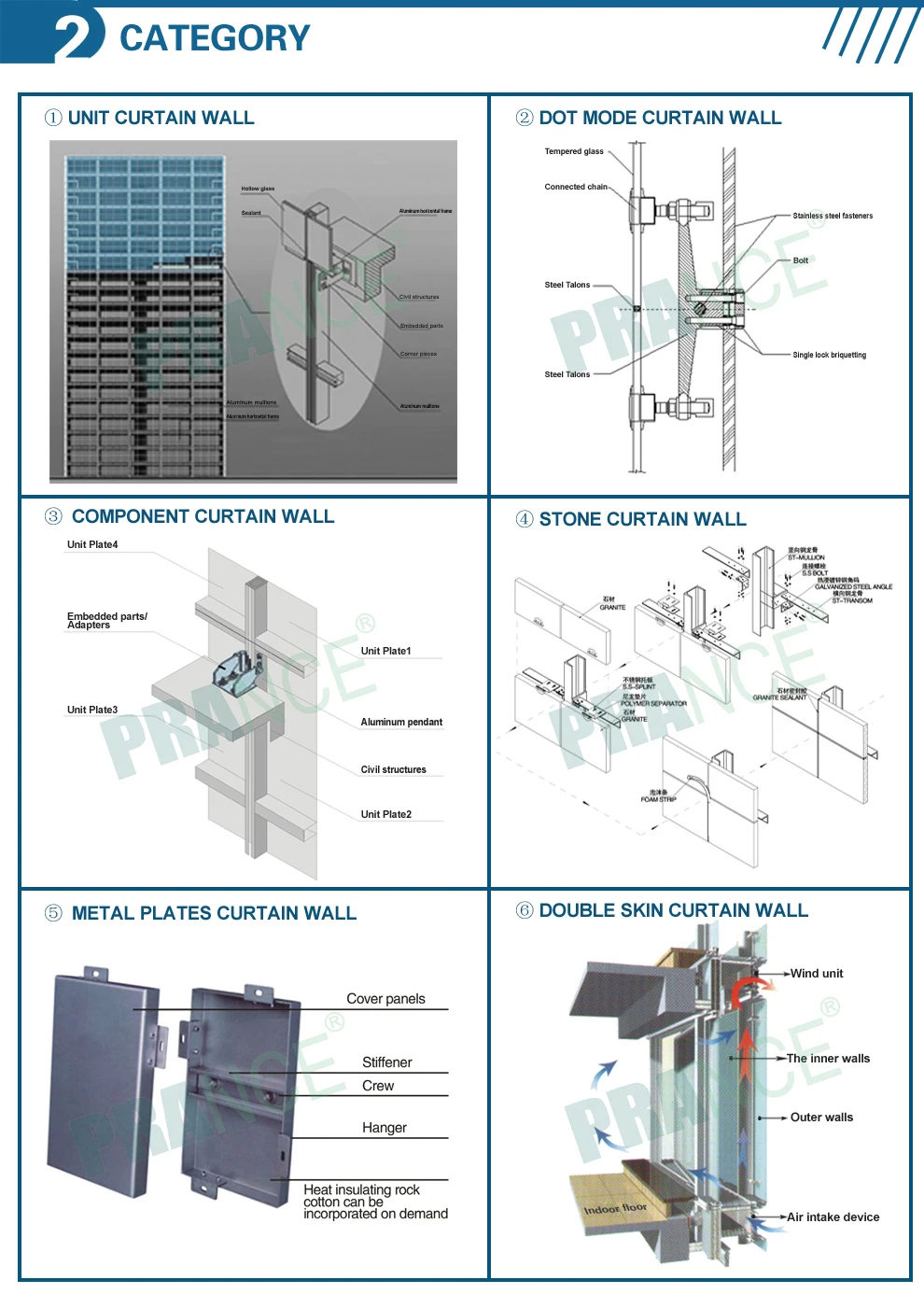

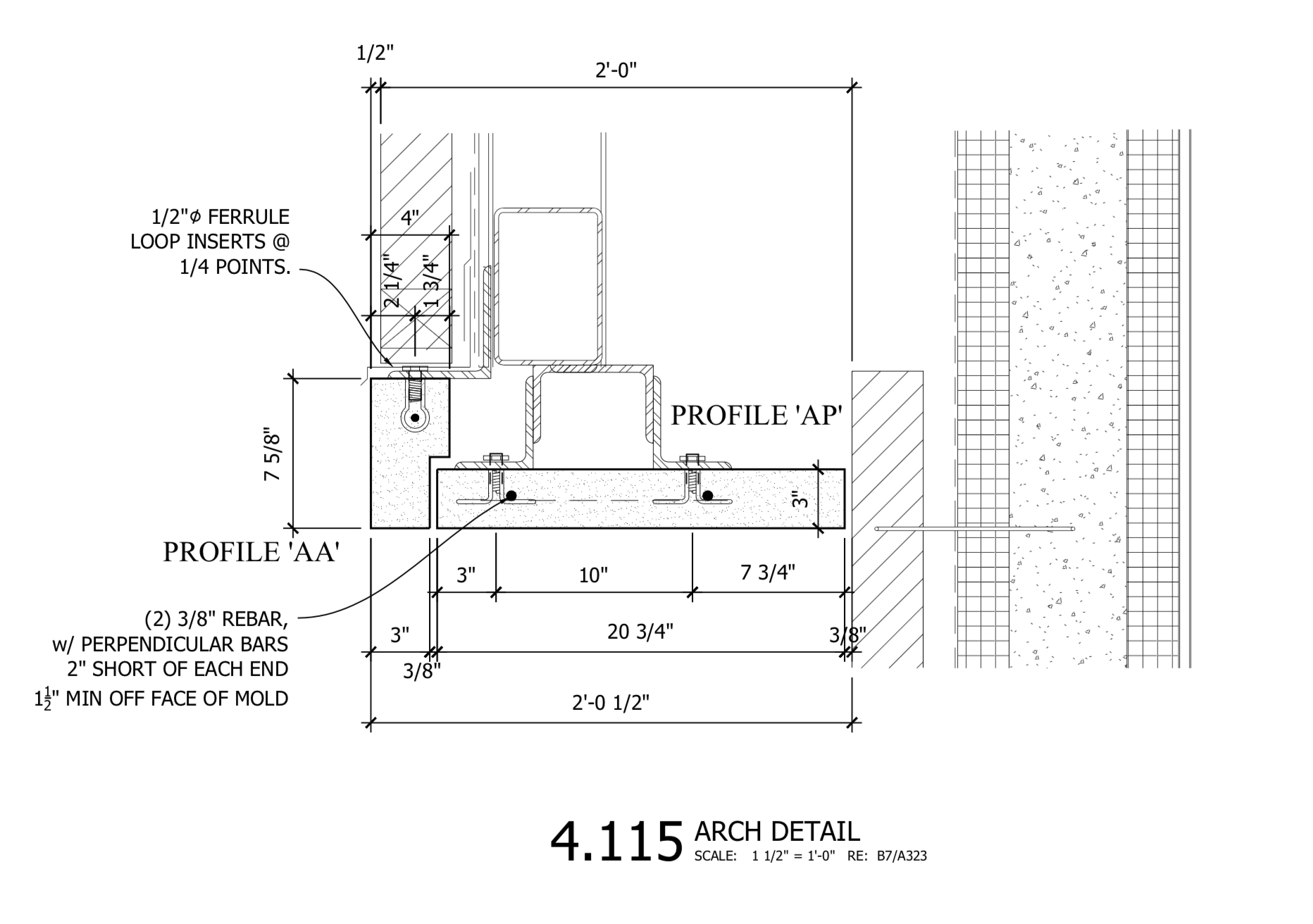

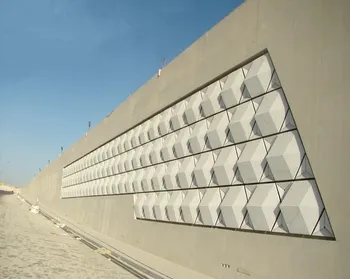

Glass fiber reinforced concrete gfrc panels are comprised of a 1 thick composite glass fiber concrete skin that is mechanically attached by flexible steel pins to a sturdy steel frame.

The ingredients for a gfrc wall panel are.

The glass fiber adds flexural tensile and impact strength.

Gfrc is made from portland cement and aggregate and reinforced with alkali resistant glass fiber reinforcement.

Gfrc glass fiber reinforced concrete is lighter stronger faster than normal concrete.

This expressions ltd basic gfrc mix recipe works great for gfrc countertops sinks and furniture pieces.

Our gfrc wall panels are typically made at 3 4 1 thick.

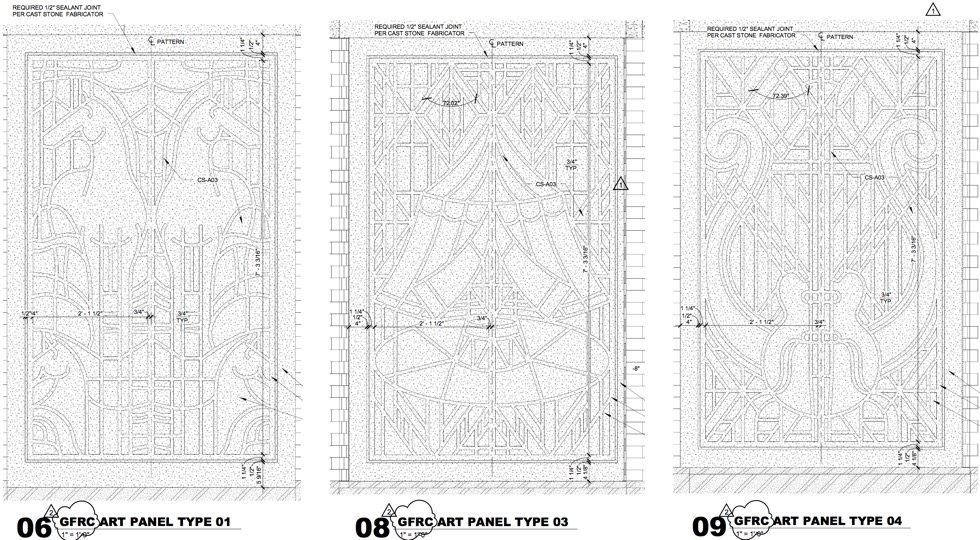

Our concrete wall panels are cast using a glass fiber reinforced concrete gfrc matrix a high performance concrete that allows the panels to be made lighter stronger thinner and larger then conventional concrete.

Polycon products made in czech republic and trusted as the worlds highest quality gfrc glass fiber reinforced concrete panel.

By expressions ltd equipme.

This material has advantages that are relevant for every type of design project.

Gfrc glass fiber reinforced concrete mix.

In gfrc cladding panels the strength of the gfrc composite combined with the steel stud frame allows the production of a strong yet lightweight architectural cladding.

Gfrc pieces can be de molded as early as 24 hours.

With its ability to withstand the elements light weight and outstanding customization capabilities gfrc is by far one of the top design materials for many.

Gfrc panels are an excellent choice for high rise buildings in areas of high seismic activity and for very decorative and intricate shapes and applications.

Cladding concepts is the proud united states partner for polycon brand glass fiber reinforced concrete.